Cut Crystal Guide: Patterns, Value & Identifying Marks!

Ever wondered what truly sets apart a simple glass from a dazzling piece of crystal? The secret lies in the intricate dance of light and shadow, a testament to the artistry of "crystal cut," a process that elevates ordinary glass into a breathtaking spectacle. This isn't merely about aesthetics; it's about heritage, craftsmanship, and the enduring allure of luxury.

Consider the subtle differences: cut glass and crystal boast sharper details, patterns that are more defined and precise. In contrast, pressed glass often feels smoother to the touch, the patterns less crisp, bearing the gentle wear of time. Only when patterns are meticulously cut onto the surface of a glass object by hand, using powered cutting wheels, can it genuinely be defined as "cut" crystal. The absence of mold marks or seams is another telltale sign, a hallmark of the handcrafted nature of these exquisite pieces. Some even claim that authentic "crystal cut" may exhibit small imperfections, such as tiny bubbles, swirls, or minute variations in the glass – subtle reminders of the human touch that went into their creation.

| Attribute | Details |

|---|---|

| Craft/Technique | Crystal Cutting |

| Description | A skilled artisan who transforms ordinary glass into exquisite crystal pieces through precise cutting techniques. |

| Tools and Materials | Powered cutting wheels, diamond saws, grinding wheels, polishing compounds, lead crystal blanks, grease pencils, soft brushes |

| Skills | Artistic vision, precision, hand-eye coordination, knowledge of glass properties, understanding of cutting techniques |

| Process | Design and preparation, cutting, grinding, polishing, quality inspection |

| Output | Cut crystal glassware (bowls, stemware, vases, ornaments) and custom installations |

| Impact | Enhancing the beauty of everyday objects, preserving traditional craftsmanship, creating valuable and artistic pieces |

| Further Information | Waterford Crystal |

In the heart of Ireland, nestled within the scenic town of Dingle, Co. Kerry, lies a workshop where the ancient art of "crystal cut" thrives. Located in a Gaeltacht area, where the Irish language is still woven into the fabric of daily life, these artisans dedicate themselves to producing 100% mouth-blown and hand-cut crystal. Specializing in colored hand-cut crystal, they have rapidly ascended to become one of Ireland's leading crystal manufacturers. Their pieces aren't mere objects; they are works of art, imbued with a legacy of skill and passion.

- Unveiling The Enigmatic Discover The True Identity Of Omar Chaparros Wife

- Unveiling Helene Walsh A Journey Of Global Journalism And Unwavering Truth

The allure of "crystal cut" isn't confined to Ireland. Hawkes Crystal, for instance, represents a tradition of hand-cut brilliance in Tiffin, Ohio, where master cutter and designer Aiden J. continues to create stunning pieces. These artisans specialize in brilliant cut designs, transforming fine crystal into bowls, stemware, barware, vases, custom window installations, and ornaments. Their dedication to the craft echoes the sentiment of crystal artisans worldwide: a pursuit of perfection, a dedication to preserving an age-old art form.

The history of "crystal cut" is rich and fascinating. The "brilliant" period of glass, spanning from 1880 to 1905, marked a peak in the popularity of cut crystal. The allure of luxury played a significant role in its rise, transforming ordinary tableware into objects of desire. Even today, vintage crystal patterns, identified by their clear or tinted surfaces and intricate motifs, hold a special place in the hearts of collectors. The sunburst pattern, with its central star and radiating beams, remains particularly popular, its bright, sharp cuts imbuing the glass with a captivating vibrancy.

But what are the distinguishing characteristics of authentic "cut leaded crystal" (or cut glass)? Firstly, the weight: the heavier the cut glass, the more valuable it is perceived to be. This density stems from the lead content, which replaces the calcium found in typical potash glass. Lead glass, often simply called "crystal," allows for deeper, more intricate cuts, resulting in the sharp, defined patterns that are so characteristic. These patterns, thicker and sharper than those found on pressed glass, reflect light with exceptional brilliance.

- Unveiling The Enigma Exploring The Multifaceted Genre Of Marilyn Manson

- Unveiling The Intriguing Net Worth Of Linda Tripp

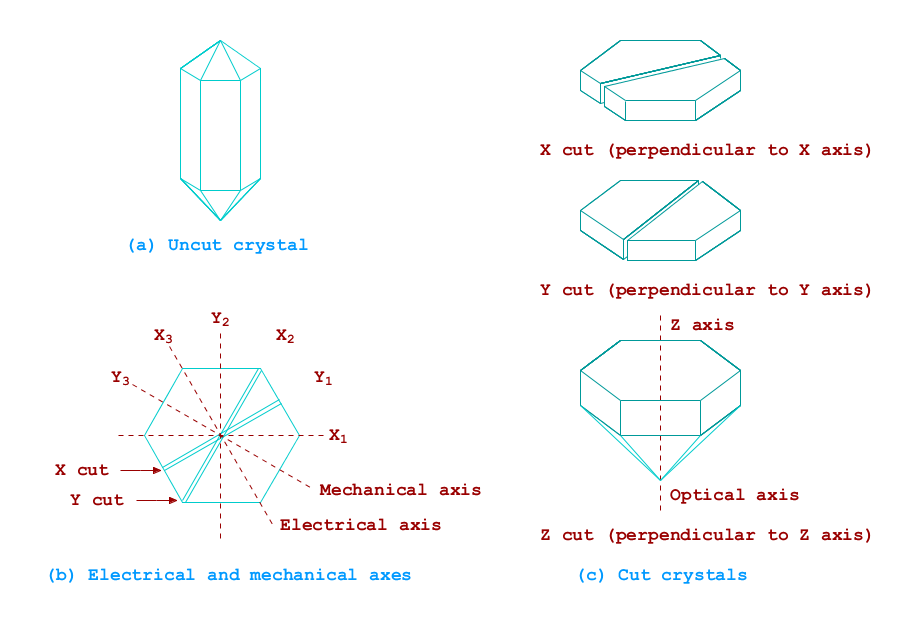

The process of creating "crystal cut" is both demanding and rewarding. It's a technique that requires five years to perfect, a testament to the dedication and skill of the artisans involved. There are three main styles of cutting, each differing in the width and depth of the cutting wheel used. This ancient technique, still practiced in Sri Lanka, demands precision and a steady hand. The tools of the trade include diamond saws for cutting the crystal into manageable sizes, and grinding wheels in various grit sizes for shaping and smoothing the surface. The process begins with deciding on the shape based on the crystal's natural form and intended use. A grease pencil or marker is then used to outline the cut, guiding the artisan as they carefully remove material. Avoiding excessive pressure is crucial to prevent breakage.

Beyond its aesthetic appeal, "crystal cut" also finds applications in other fields. Quartz blanks, produced through precise cutting techniques, possess a good temperature coefficient, making them valuable in various technological applications. The "herzschlag" of an application, as described in German, can even be dictated by the steady rhythm of a thin, oscillating quartz disc. However, the matter is often far more complex, highlighting the multifaceted nature of crystal cutting.The user may get sharp crystal and cuts the target with 1/6 (16.7%) chance to land a critical hit.

Whether used for tableware, stemware, giftware, or lighting, "crystal cut" elevates ordinary objects into extraordinary works of art. The range of possibilities is vast, from the delicate curves of a wine glass to the intricate facets of a crystal sphere. Indeed, crystal spheres are often used to fill space with clearing or positive energy, scrying and meditations, emitting energy gently in all directions.

Caring for "crystal cut" requires a gentle touch. Most crystal comes in its original packing paper and should be washed before use. This guide covers the different types of crystal glassware and their care instructions, so you can choose glasses that brighten your table and last a lifetime.

Companies like Kusak Cut Glass Works, built a reputation for quality and sold corporate and golf awards division, synonymous with quality, integrity, and above all honesty, embody the enduring legacy of "crystal cut." Their mission is for the name crystal cut tool to be recognized as synonymous with quality. The company has grown steadily since its incorporation in 1968.

Ultimately, "crystal cut" represents more than just a technique; it's a celebration of craftsmanship, artistry, and the enduring allure of beauty. It's about transforming ordinary materials into extraordinary objects that capture the imagination and enrich our lives.

In conclusion, while all crystal is a type of glass, not all glass can be accurately called crystal. Cut leaded crystal (or cut glass) possesses three distinct characteristics, making it a prized material with unique qualities and a long history of craftsmanship. You can start your project with crystal cut now because Crystal cut is one of over 3,000 colors you can find, coordinate, and preview on www.behr.com.

While a mixed cut, the barion cut also deserves a category of its own.It is designed to cut through hard materials like gemstones with ease.There are various types of diamond saws available, including trim saws for smaller pieces and slab saws for larger rocks.Grinding wheels come in different grit sizes and are used to shape and smooth the crystal after it has been cut by the diamond sawDecide on the shape based on the crystal\u2019s natural form and intended use.Remove dirt or debris using warm water and a soft brush.Use a grease pencil or marker to outline the cut.Use a diamond saw to cut the crystal into a manageable size.Avoid applying too much pressure to prevent

- Unveiling The Extraordinary World Of Harold Gould An Actors Journey

- Discover The Evolution Of Keana Barnes A Journey Of Style And Social Impact

How to cut gemstones Quartz YouTube

Your Guide to the Top 10 Cut Crystal Shapes House of Formlab

Illustration 6