Film Capacitors: A Deep Dive + Where To Buy Them!

Ever pondered the unsung heroes quietly powering our modern world? It's the film capacitor, a seemingly simple component that underpins a vast array of electronic devices, from the smallest handheld gadget to the largest industrial power system. Their reliable performance and versatile applications make them indispensable in today's technology landscape.

Film capacitors, at their core, rely on thin plastic films as their dielectric material. This dielectric, sandwiched between conductive electrodes, dictates the capacitor's ability to store electrical energy. The choice of plastic film directly impacts the capacitor's characteristics, such as its voltage rating, temperature stability, and frequency response. This fundamental design principle allows for a wide variety of film capacitor types tailored to specific applications. We see them employed in everything from smoothing power supply voltages to precisely tuning resonant circuits.

| Attribute | Details |

|---|---|

| Basic Definition | Passive electronic component that stores electrical energy in an electric field. Utilizes a plastic film as the dielectric material. |

| Dielectric Material | Various plastic films including Polypropylene (PP), Polyester (PET), Polyethylene Naphthalate (PEN), and Polystyrene (PS). The choice impacts performance characteristics. |

| Capacitance Range | Spans a wide range, typically from picofarads (pF) to several microfarads (µF), depending on the film material and construction. |

| Voltage Rating | Available in voltage ratings from a few volts to several kilovolts, suitable for diverse applications. |

| Key Characteristics |

|

| Types |

|

| Applications |

|

| Package Styles |

|

| Manufacturers | Vishay, Kemet, TDK, Panasonic, WIMA, Cornell Dubilier, AVX, Nichicon, EPCOS (now part of TDK). |

| Key Parameters to Consider |

|

| Advantages |

|

| Disadvantages |

|

The world of film capacitors is diverse, offering a wide array of options to suit various needs. Consider, for instance, AC and DC rated film capacitors, crucial for industrial power applications. These capacitors are designed to withstand the rigors of high-voltage, high-current environments, ensuring reliable performance in demanding settings. Then there are specialized types like X2 and Y2 capacitors, vital for arc suppression and ensuring safety in electrical equipment. These safety-rated capacitors are strategically placed to mitigate the risk of electrical shock and fire hazards, providing a crucial layer of protection. The selection often depends on a detailed analysis of the application's specific requirements.

- Unveiling Jayson Tatums Beliefs A Journey Into Faith And Spirituality

- Unveiling The Secrets Of Canoeing Success Discoveries From Balzs Levente

The choice of the right film capacitor is often driven by the specific application and its demands. Consider the nuances of choosing between different types: should you opt for a polypropylene cap, or is a more specific type needed? This decision hinges on several factors, including the desired performance characteristics, operating conditions, and cost considerations. For example, DC link film capacitors are frequently used in high-power applications like electric vehicle inverters, requiring robust performance and long-term reliability. General film capacitors offer a broader range of uses, while AC and pulse film capacitors excel in applications involving alternating currents and rapid voltage changes.

The variety of film capacitor brands further complicates the selection process. Which brand reigns supreme: WIMA, Nichicon, Kemet, or EPCOS/TDK? Each manufacturer brings its own expertise and unique product offerings to the table. WIMA, for instance, is renowned for its high-quality film capacitors used in audio applications, while Nichicon offers a wide range of capacitors for various industrial and consumer electronics. Kemet and EPCOS/TDK are also established players in the market, providing reliable components for demanding applications. Navigating this landscape requires a keen understanding of each brand's strengths and weaknesses.

For those venturing into the world of film capacitors, the sheer number of options can be overwhelming. The confusion is understandable, given the diverse range of types, brands, and specifications available. However, by breaking down the key parameters and understanding the application requirements, the selection process becomes more manageable. Factors such as capacitance value, voltage rating, temperature stability, and equivalent series resistance (ESR) play crucial roles in determining the suitability of a film capacitor for a given task.

- Uncover Hidden Treasures With Frances Christie On Antiques Roadshow

- Uncover Russ Net Worth Discoveries And Financial Insights

Sourcing film capacitors often leads to online distributors like Mouser Electronics. These platforms offer a convenient way to browse a vast selection of components from various manufacturers. However, navigating these websites requires careful attention to detail, ensuring that the chosen capacitor meets the specific requirements of the application. Pay close attention to the datasheet, which provides critical information about the capacitor's performance characteristics and limitations.

Film capacitors come in various styles, each with its own advantages and disadvantages. Radial leaded film capacitors, with their leads extending from the bottom, are a common choice for through-hole mounting. Axial leaded film capacitors, on the other hand, have leads extending from opposite ends, offering a different mounting configuration. Surface mount devices (SMD) are designed for direct mounting on circuit boards, enabling compact designs and automated assembly. The choice of package style often depends on the specific design constraints and manufacturing processes.

Beyond traditional film capacitors, specialized types like hydrodynamic bearings, also known as fluid film bearings, find applications in rotating machinery. These bearings utilize a thin film of fluid to separate moving surfaces, reducing friction and wear. They come in several types, including radial tilting pad bearings, thrust bearings for axial displacement, and journal sleeve bearings, each designed for specific load and speed conditions. While distinct from film capacitors in their function, hydrodynamic bearings showcase the broader application of film-based technologies in engineering.

In certain applications, designers may prefer polyester film capacitors for their higher ESR. However, this can present a challenge when attempting to achieve a specific capacitance value by placing capacitors in parallel. The increased ESR of the polyester capacitors may counteract the desired effect, leading to suboptimal performance. This highlights the importance of carefully considering the trade-offs between different capacitor types and their impact on circuit behavior.

The nuances of film capacitor selection become particularly apparent when dealing with audio equipment. For instance, taming the midrange and highs on Klipsch speakers, where original oil caps were replaced with polypropylenes, requires careful consideration of the capacitor's impact on the audio signal. The choice of film capacitor can significantly alter the sound characteristics, influencing the overall listening experience. Experimentation and careful listening are often necessary to achieve the desired sonic outcome.

The fundamental principle behind film capacitors remains consistent: the use of plastic film materials as a dielectric. This design principle provides a foundation for a wide range of capacitor types, each tailored to specific applications. The film material, electrode configuration, and packaging style all contribute to the capacitor's overall performance and suitability for a given task.

Film capacitors with radial leads, typically made of tinned wire, are widely used in various electronic circuits. The radial leads are electrically welded to the metal layer on the ends of the capacitor winding, ensuring a reliable connection. Different winding constructions are employed to optimize the capacitor's performance characteristics, such as its capacitance, voltage rating, and frequency response.

Mouser Electronics stands as a prominent distributor of film capacitors from industry-leading manufacturers. They offer a comprehensive selection of capacitors from brands like Cornell Dubilier, Kemet, Kyocera AVX, Panasonic, TDK, Vishay, and WIMA, providing engineers and designers with a wide range of options to choose from. Their platform offers inventory information, pricing details, and datasheets, facilitating the selection process.

Product information and news regarding film capacitors are readily available from manufacturers like Panasonic. These resources provide valuable insights into the latest developments in film capacitor technology, including new materials, designs, and applications. Staying informed about these advancements is crucial for engineers and designers seeking to optimize their designs and stay ahead of the curve.

Mouser specifically offers inventory, pricing, and datasheets for polyester radial film capacitors, catering to the needs of designers seeking this particular type of capacitor. The R71H 125°C PFC film radial capacitor, for example, is a popular choice for power factor correction applications, offering high-temperature performance and reliable operation.

While the term "radial film" might evoke images of cinematographic techniques, it's essential to differentiate it from the realm of electronic components. Radial film in cinema refers to a distinctive approach that revolves around the circular motion of the camera, departing from traditional linear or lateral movements. This technique aims to create an immersive experience for the viewer, drawing them into the story in a unique way. The term, therefore, has distinct meanings in different contexts.

In the context of filmmaking, radial film has gained traction as a buzzword, signifying a shift towards more immersive and engaging storytelling. It's not just about watching movies anymore; it's about experiencing them on a deeper level. Understanding radial film can open up a whole new world of possibilities for filmmakers, cinephiles, and anyone who appreciates a good story. This technique showcases the power of visual storytelling and its ability to captivate audiences.

Film capacitors, on the other hand, find their place in the world of electronic equipment. They are packaged in common and usual industry styles, ensuring compatibility with various circuit board designs and manufacturing processes. These packaging styles are designed to facilitate easy installation and reliable performance in demanding electronic applications.

In summary, film capacitors are essential components in a wide range of electronic devices, relying on plastic film materials as their dielectric. Their versatile applications, reliable performance, and diverse types make them indispensable in today's technology landscape. From power supplies to audio equipment, film capacitors play a crucial role in shaping the functionality and performance of modern electronics.

- Unveiling The Secrets Of Aimsey Age Discoveries And Insights

- Unveiling Omar Rudberg Unlocking His Talent Charisma And Inspiring Journey

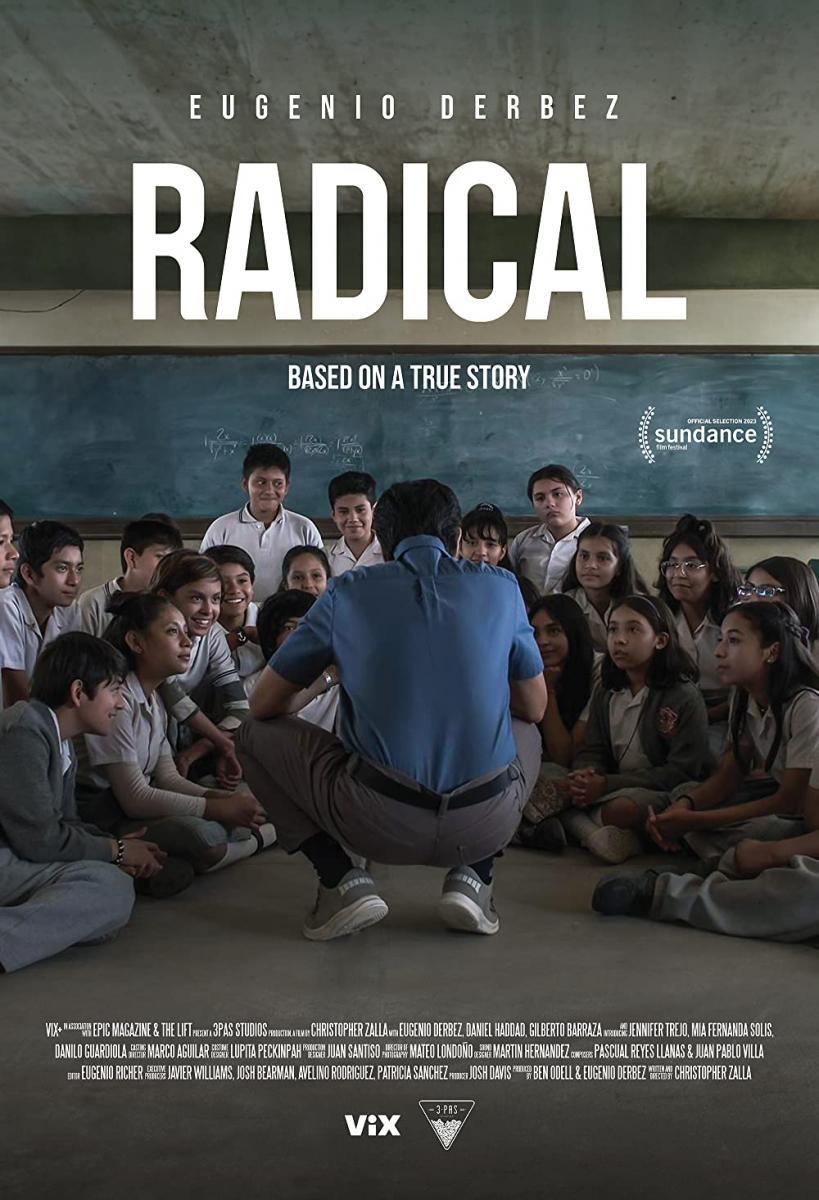

Sección visual de Radical FilmAffinity

Eventfilme Radialfilms Baden Württemberg

Radical (2023)